Equipped with the options humidification and dehumidification, a temperature test cabinet becomes a climatic test cabinet, which is suitable for various applications in research and quality control. You have the choice between the appliances of the Eco-Line, which are working exclusively with evaporation humidifiers, and those of the Premium-Line offering alternatively also the ultrasonic atomization. Combined with the different possibilities of dehumidification, the humidity range of the ultrasonic atomization extends from 20 % to 95 %. Thanks to the variety of options and accessories, the RUMED® program can be customized flexibly to your requirements. The used advanced technology with the controller Control2015 touch ensures a perfect interaction of temperature and humidity.

Storage at constant climates according to the ICH guideline in the pharmaceutical industry.

Freeze-thaw alternating tests in building material testing show the durability of the material.

Avoidance of condensation with temperature alternating tests by expansion of dry compressed air, such as for clock production.

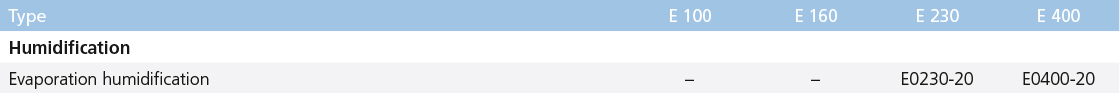

integrated into the Control2015 touch. The sensor is a temperature-compensated, capacitive sensor, which can be calibrated. The water supply is either realized automatically by direct connection to the drinking water supply or by periodical manual refilling of drinking water. The evaporation humidifier is the exclusive way of humidification of the ECO Appliance

Line. The Premium-Line furthermore includes the high-precision controllable ultrasonic atomization.