Please choose the options, which are relevant for the product enquiry.

Extension of the minimum temperature to -20 °C.

Ion exchanger for direct connection to the drinking water pipe, if demineralized water supply is not available.

Canister for water supply at installation places without water connection.

A 45 mm duct in the lateral panel allows insertion of measuring lines and hoses into the test room. Delivery including cover.

Gas-tight closing plug, matching to the tubular port. The gasket system with a flexibility in the range of 4 mm to 23 mm is based on a rubber module with removable skins and can be adapted to the cables, tubes etc. in different sizes.

Test room socket for connection of shakers, magnetic mixers etc. in the test room. Switching-on times can be freely programmed by means of the CONTROL2015 touch.

Export execution for power supply 110 V/60 Hz.

Additional measuring sensor PT1000 for temperature control and recording of specimen.

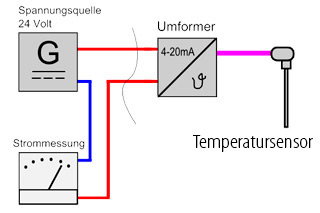

Analogue output test room temperature for external recorder Signal 0-10 V, 0-20 mA, 4-20 mA

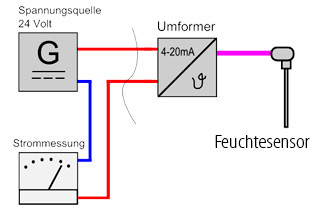

Analogue output test room humidity for external recorder Signal 0-10 V, 0-20 mA, 4-20 mA

- Monitoring of up to 32 appliances - Compatible with Control 2000 and Control2015 touch - Data logging and graph representation - Logging of door openings with time stamp - Logging of alarms with time stamp - Automated daily print is possible - Weekly and monthly print - Archiving per day and control circuit - Automated backup on server drive

- Monitoring of appliances with Control2015 touch - Data safety in conformity with the guidelines 21CFR Part 11 - All events are recorded in a digital logbook, inseparably connected with the recorded data. - Signature in connection with the user management of the appliances - Automated prints - Automated backup on server drive

Calibration on site with 9 spatially distributed sensors with a temperature value.

Calibration on site with 9 spatially distributed sensors with a temperature/humidity value.

Calibration on site with 9 spatially distributed sensors with a temperature value.

Calibration on site with 9 spatially distributed sensors with a temperature/humidity value.

We are always ready to support the validation of your appliances. If desired, the validation can be executed by our company. The validation includes the necessary measurements, as well as any documents, such as DQ, IQ, OQ and PQ, manuals, wiring diagrams, plans, appliance logbook, manufacturer certificates for the sensors and for the most important components. If required, we are also at your disposal for the annual recalibration.

Execution and documentation of the design qualification, qualification of installation and operation qualification including calibration on site with 9 spatially distributed sensors with a temperature value on site.

Execution and documentation of the design qualification, qualification of installation and operation qualification including calibration on site with 9 spatially distributed sensors with a temperature/humidity value on site.

Execution and documentation of the performance qualification including calibration on site with 9 spatially distributed sensors with a temperature value on site.

Execution and documentation of the performance qualification including calibration on site with 9 spatially distributed sensors with a temperature/humidity value on site.