Equipped with the options humidification and dehumidification, a temperature test cabinet becomes a climatic test cabinet, which is suitable for various applications in research and quality control. You have the choice between the appliances of the Eco-Line, which are working exclusively with evaporation humidifiers, and those of the Premium-Line offering alternatively also the ultrasonic atomization. Combined with the different possibilities of dehumidification, the humidity range of the ultrasonic atomization extends from 20 % to 95 %. Thanks to the variety of options and accessories, the RUMED® program can be customized flexibly to your requirements. The used advanced technology with the controller Control2015 touch ensures a perfect interaction of temperature and humidity.

Aerosol mist without heat introduction into the test room.

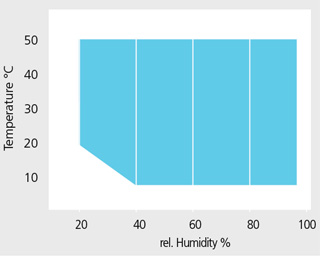

For all applications requiring an exact setting of the air humidity, the ultrasonic atomization in combination with the dehumidification methods is the best choice. This way of humidification is only available in the Premium-Line. The desired humidity can be preselected by means of the electronic PID-controller, which is integrated in the Control2015 touch. The adjacent diagram gives an overview of the application range. The dehumidification can be effected in three different ways: as standard dehumidification, as deep dehumidification and as compressed air dehumidification

This combination of humidification and dehumidification allows quick humidity variations and a wide range of climate simulations. For instance, it is possible to achieve high humidity values at low temperature values.

The ultrasonic atomization has many further advantages: In comparison with the steam humidification, the ultrasonic atomization avoids an unintended heating of the test room. The humidification by means of an ultrasonic atomizer is considerably more economic regarding energy and water consumption and, in addition, requires only low maintenance, since demineralized water is used.

Storage at constant climates according to the ICH guideline in the pharmaceutical industry.

Freeze-thaw alternating tests in building material testing show the durability of the material.

Avoidance of condensation with temperature alternating tests by expansion of dry compressed air, such as for clock production.

Canister for water supply at installation places without water connection.

Order No.: P9920-02

Test room bottom with slope to the condensate drain.

Ion exchanger for direct connection to the drinking water pipe, if demineralized water supply is not available.

Order No.: P9920-01

The dehumidification is realized by condensation or freezing of the water vapour contained in the air at a plate heat-exchanger of stainless steel in special design. Periodical hot gas defrosting thaws the frozen water, which will be dripping into the condensate drain.

This version is a modification of the standard dehumidification with higher efficiency. The air flow above the humidifier is controlled or reduced by means of a special valve.

Extremely low humidity values at low temperatures can be achieved by our compressed air dehumidification. The customer-supplied dry compressed air will expand in the test room, thus reducing the relative humidity. This application is particularly advantageous for temperature alternating tests, where it is essential, that condensation is to be avoided completely.

The ultrasonic humidification is connected directly to the demineralized water supply of the customer. If such a supply is not existing, the humidifier can be connected to the drinking water pipe via an ion exchanger. If a drinking water supply is not within reach or if it is not desired, a manually refillable canister can be used.